Create the conditions for a consistently high standard

of quality of your soybean products.

YOUR CHALLENGE

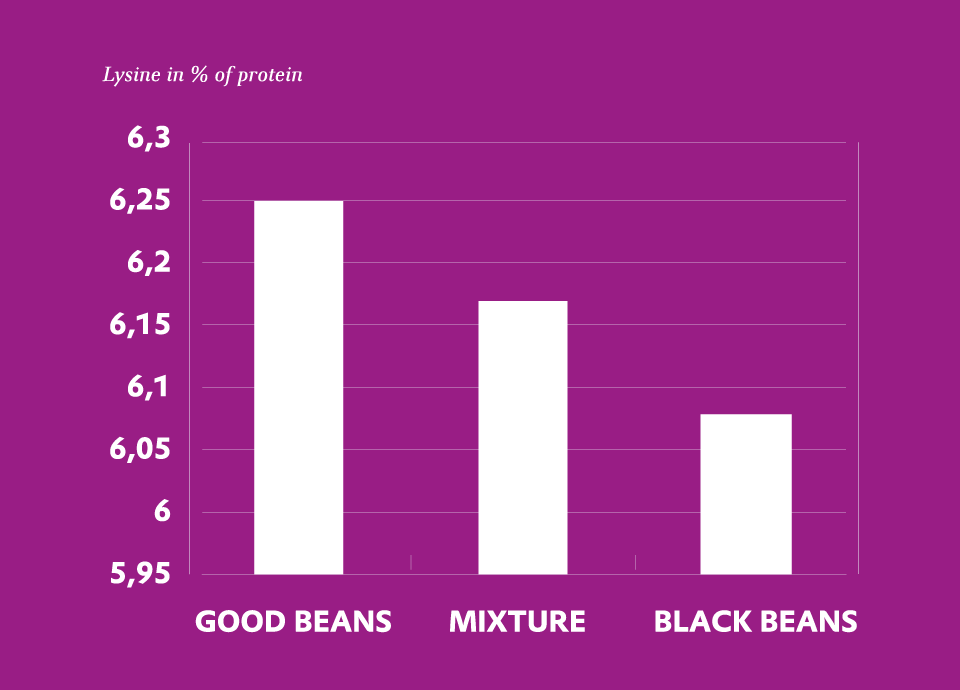

Soybeans require a certain degree of heat treatment to target antinutritional components like trypsin inhibitors and lectins. Yet, excessive heating negatively affects the total content of valuable amino acids like lysine, cystine and arginine. If the processing is not done properly, this can worsen the digestibility of the soy product, resulting in decreased nutritional quality.

Heat damage decreases the nutritional

quality of soybean products. ▸

OUR SOLUTION

Use AMINONIR® to determine the impact of heat treatment on the quality of your soybean products. Finetune the treatment to get the best possible product. Once you have scanned the soybean samples and uploaded the spectra to Evonik, you will receive a complete evaluation within minutes.

Get an estimation of the degree of processing based on the near infrared (NIR) calibrations for the following well established parameters:

• Protein solubility in potassium hydroxide (KOH)

• Trypsin inhibitor activity (TIA)

• Reactive lysine

• Ratio of reactive lysine to total lysine

You also get the corrected amino acid values based on the measured degree of processing so you can maximize digestibility.

YOUR BENEFITS FROM AMINONIR® AT A GLANCE

Quick spot checks of raw soybeans, soybean full-fat, soybean expellers and soybean meals

Analytical data to optimize the quality of your soybean products

High sample throughput at low cost

Comprehensive and clear report

Ideal conditions for price negotiations (quality-based sale)

Implementation and maintenance support

Ongoing online expert support

SEE THE OTHER FIELDS OF APPLICATION THAT AMINONIR® IS PERFECTLY SUITED FOR:

Feed millers

Feed mills receive and release thousands of shipments, which requires fast but nevertheless accurate and precise solutions for quality control. Carry out precise nutrient evaluations of more than 60 different ingredients.

Producers of corn DDGS

Carry out precise nutrient evaluations of corn and corn DDGS and gain deeper insights into qualitative differences between corn deliveries, different batches of corn DDGS and changes in quality over time.

Producers of fish meals

Lysine and sulfur-containing amino acids are especially valuable components for fish meal, as they complement plant-based proteins like soy. Yet, the amount of amino acids contained in fish meal varies widely.

Producers of mustard or rapeseed meals

Mustard and rapeseed meals vary greatly in their content of antinutritional factors like glucosinolates and erucic acid. In addition, processing has a huge impact on heat labile nutrients. Optimize the production and marketing of your mustard and rapeseed meals.

Producers of animal byproduct meals

Animal byproduct meals are valuable due to their high amino acid content but are processed in many different ways. That’s why their quality can vary drastically. Use quick spot checks to demonstrate the quality of your products and to differentiate in the market.