The AMINONIR® services offer reliable nutritional analysis in a minimal time – even with unground raw materials. Easy to perform, fast to implement, invaluable for business performance.

YOUR CHALLENGE

You want your livestock to always be healthy and strong, with realistic and cost-effective effort. Feed with the best nutritional values ensures this. Raw material variability, price volatility, fierce competition – stakeholders throughout the livestock feed value chain face tough challenges.

Whether you are a feed miller, soybean processor or a producer of corn DDGS (distiller's dried grains with solubles), of rapeseed or mustard meal, fish meal or animal byproduct meals:

Reliable and timely information about the nutritional value of your raw materials and products, allows you to optimize your processes and gain a competitive advantage based on verifiably superior quality.

Download Whitepaper now

This Whitepaper discusses the challenges faced by the animal feed industry, including rising costs and the variability in nutritional values of feed ingredients like soybean products. NIR technology, such as Evonik's AMINONIR® service, can help mitigate these challenges by providing accurate information for quality control and improving animal performance and feed efficiency. The paper is authored by Dr. Markus Wiltafsky-Martin, and provides valuable insights for those in the animal feed industry.

OUR SOLUTION

In response to those challenges, Evonik has developed a comprehensive range of analytical solutions that equip you with precise and up-to-date nutritional data on feed ingredients and finished feeds. The AMINONIR® services use near infrared (NIR) spectrometry to determine key factors like amino acid contents.

HOW DOES IT WORK?

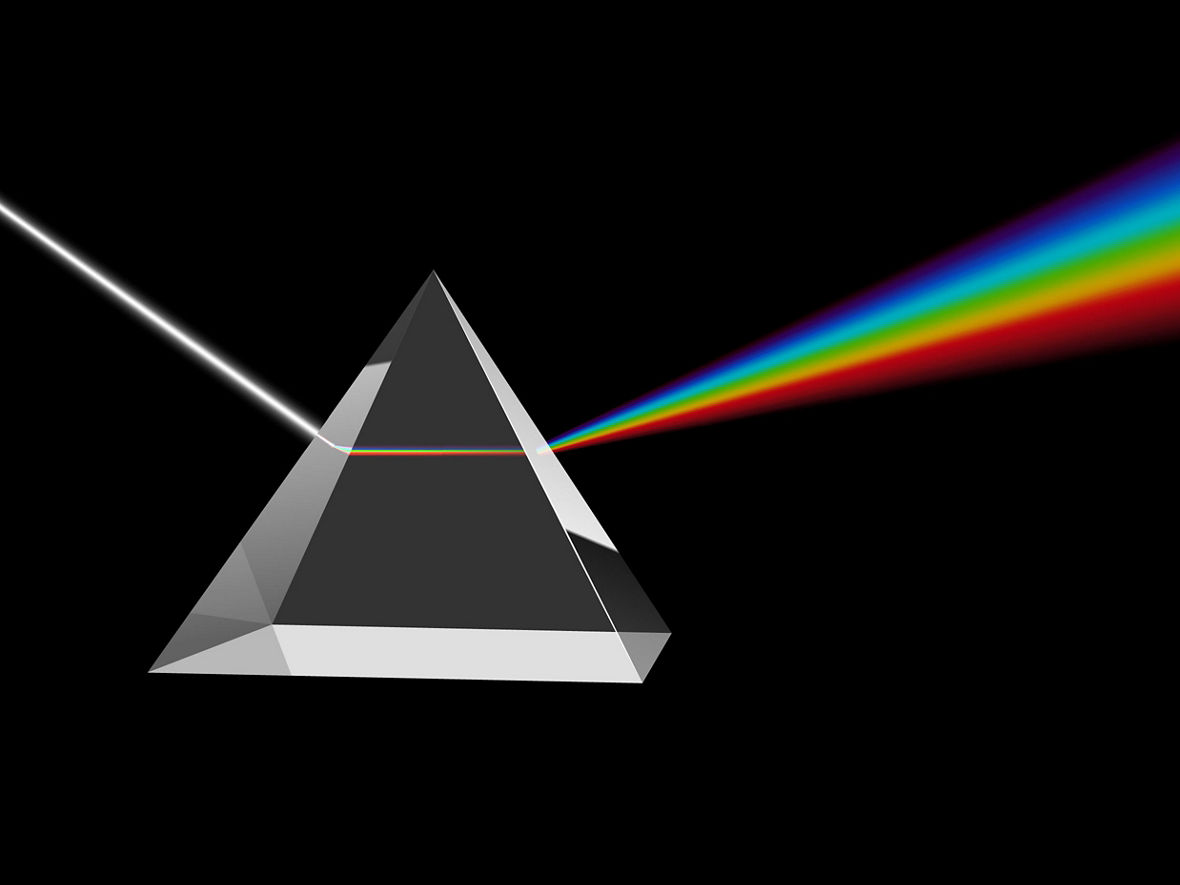

In NIR spectrometry, invisible near infrared light is beamed to a sample, causing molecules in the sample to vibrate. This interaction with the molecules consumes energy by absorbing elements of the introduced light. In the case of liquid samples, residual light passes through the material, while solid samples reflect the light. This light is measured with a detector and gives a spectrum.

The spectral information is further used and evaluated for example to identify unknown samples (fingerprinting) or to estimate its nutritional composition via the application of NIR calibrations.

GET YOUR RESULTS IN FOUR EASY STEPS

Step 1: Fill the cup

AMINONIR® supports a huge variety of raw materials and finished feeds that can be scanned in order to receive detailed information about their nutritional values.

Step 2: Scan the sample

Place the sample in the NIR cup. Evonik’s technology can analyze the sample as it is (unground or ground). For AMINONIR® services you can use NIR spectroscopy devices from FOSS and BRUKER.

Step 3: Upload your data

Uploading is as easy as scanning. Within seconds, you can transfer the data by web browser or via the AMINONIR® Advanced web service interface. There’s no need to select any material types or input complicated data.

Step 4: Get your report

You’ll find everything you need to know about your raw materials or finished feeds in one detailed report.

| AMINONIR® Advanced supports more than 60 raw materials and finished feeds | |

|---|---|

|

|

Technology partners

Instruments from these providers are capable of performing analyses of raw materials and finished feeds.

- FOSS DS 2500

- FOSS DS 2500 F

- FOSS DS3

- FOSS DS3F

- Bruker MPA

- Bruker MPA II

- Bruker Matrix I

- Bruker Tango

Software overview

AMINONIR® Plugin is the Evonik web service interface that allows a fully automated and seamless network integration and technical data exchange in the background, including spectra uploads and results transfer from and to Foss Mosaic and Bruker OPUS.

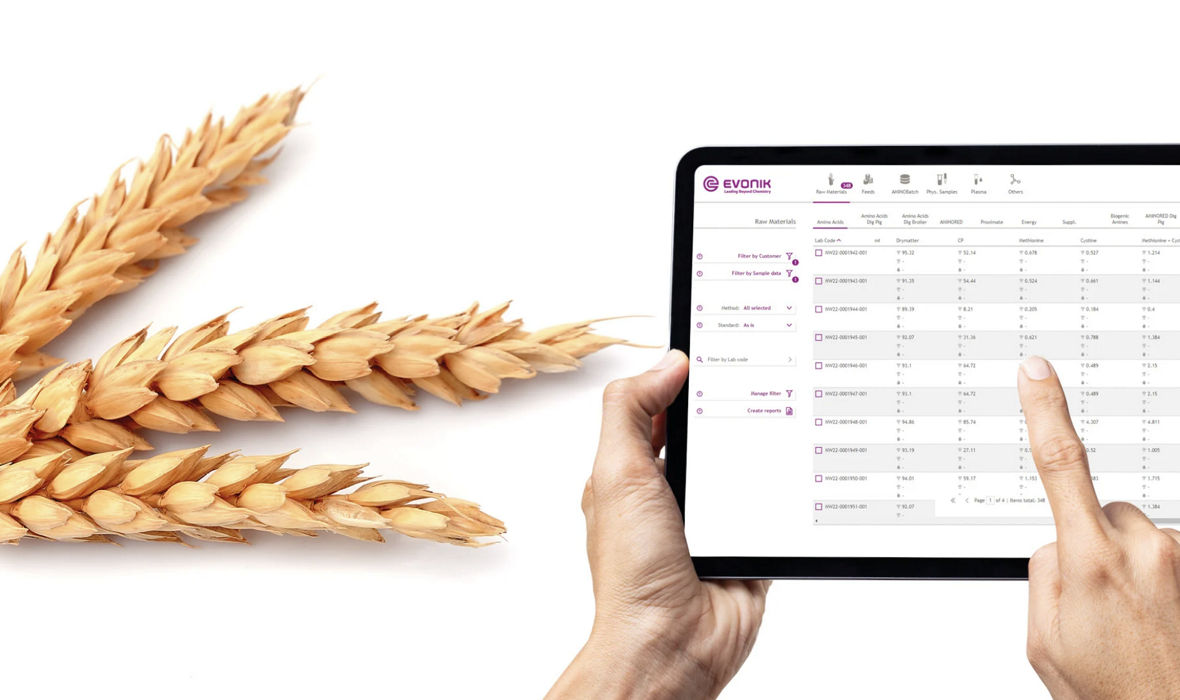

AMINONIR® Advanced 3.1 allows you to upload your spectra files via web browser in seconds. Processing occurs automatically: There’s typically no need to select material types or input complicated data, and there’s no chance for operator mistakes. Analytical Data Advanced 3.1 is a web-based tool that allows you to download the results as a PDF, Excel, CSV, or XML file, or to schedule these files as an automatic email attachment whenever new data is available.

GET IN TOUCH

You have questions about AMINONIR®?

Just leave your contact details. One of our specialists will contact you immediately.